As the summer is approaching, we’d like to wish you a sunny and successful spring and summer of 2017. The Finnish economy is finally improving and many experts are predicting an even bigger growth in the economy than before. This shows well in the Finnish metal industry where a growing number of companies are working at full capacity. There is, of course, a slight uncertainty in the market, both in Finland and elsewhere. The relations between the two Super Powers are intense, North Korea is behaving aggressively and today terrorism is a reality even in the Nordic countries. In Finnish industry, a hot topic of discussion is the labour union negotiations this autumn. This will have an effect on all the companies in the industry, even though many firms are doing well and have a positive outlook for the future. One clear sign of this is that many workshops have started investing in new machinery.

The year 2017 has started better than expected for Jame-Shaft. The order base started growing in November 2016 and is still growing strongly. The order book is now double, compared with last year and the invoicing at the beginning of the year was 26 % greater than at the same time last year. This was more than we had budgeted for at the beginning of the year, so it came as a surprise. Unfortunately, we couldn’t react quickly enough to the larger demand so we have had far too many delays in deliveries. To be honest, there hasn’t been any significant improvement in the matter yet. However, the weekly invoicing is on the rise, so we expect the situation to get better in the near future. At the same time, we can note that our invoicing in March was the best ever, exceeding the previous record by over ten percent.

In October 2016, we stated that there was no need for further investments because there were no signs of improvement in the market. How wrong we were! Nevertheless, we realized the situation had changed in the market in early December and started to plan new investments. We drew up an over two-million euro, 18-month investment plan that will be implemented at a quick pace. In addition, we purchased the first of a series of new machines, recruited 10 new factory workers and one new office worker. Our machine capacity also grew, by three lathes and one robot. All these new machines are fully functional as we speak, but they are not used to their full capacity yet. All in all, we now employ 60 people and even have several trainees at work too. As a matter of interest, we also have three youths from Portugal doing their two-month training period.

To increase capacity, we have also taken other more immediate actions. To name a few; working overtime, working in three shifts and increasing unmanned use of machines. We have even bought some of the work from the outside. In practice, these are the measures by which we have achieved a 25 % increase in invoicing from the beginning of the year. The effect of this new investment will start showing now and will further increase our capacity. The present quarter of the accounting year has only just begun, but we expect the demand to stay at the current high level in the near future as well. This means that that we will achieve a ten percent increase in turnover despite the autumn of 2016, when the turnover was at about the same level as the year before.

We have not only invested in new machinery but also invested in product testing.In addition to the existing heat treatment research that is available to us today, we can also carry out our own corrosion tests both in using salt dust and in the longer-term cabinet test with the variable circumstances of temperature and moisture.

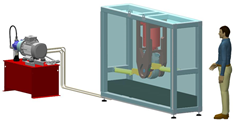

We have also planned and built a pin-bushing pair testing device that can be used to test the function of different bearings and pins and their life-time. This can be carried out as a durability test so that two different bearings can be compared with each other in the same experiment with a load similar to a real-life stress for up to 70 mm pins.

Our OHSAS 18001 occupational health- and occupational health management standard has now been audited by the DNV. A certificate will be issued during the spring. Also, ISO 9001 and 14001, Quality Management System and Environmental Management System have been audited. At the same time, we have completed renewing the air conditioning, heating and installation of LED-lighting across the factory. LED lights have clearly decreased our electricity consumption and as a result of all these changes, environmental working conditions have significantly improved. We have too, paid more attention to factory cleanliness, including standardized and reorganized work stations. We believe that you will see a big difference in the factory, so please pay us a visit.

We understand that it is ever so difficult to forecast the future. Nevertheless, we have to be able to do it as, for example, the steel orders for August need to be placed this week, i.e. week 17. In fact, this means that we need to know what we require in September. The forecasts are a big help also when preparing the budget for the next accounting period. Every piece of information regarding the situation in the autumn of 2017 would be appreciated. We hope that we can predict the requirements better this time around, so there wouldn’t be yet another big difference between the budget and the real outcome.

Even though the summer hasn’t even started, we ask you to notice that the holiday season is not that far away. We have decided that the factory will stay open the whole summer to ensure good service. Of course, the number of staff is smaller in July but all the stages of the production are available anyway. Please make sure that you keep your own holiday times in mind too, and place your orders in good time, so we can avoid problems in June and August as well.

We are doing our very best to make sure that we can return to the normal delivery times soon. With good co-operation and effective management, we can minimize the problems caused by the delays until the situation is perfectly balanced again. We wish all our customers a successful and profitable rest of the year.

Best wishes,

Mika Tuunainen

Managing Director

Jameshaft Oy