The biggest growth in the Finnish metal industry started to decline towards the end of 2018, but the beginning of 2019 was good for Jame-Shaft as well as for other companies in the business. Thanks to new investments in the metal business, the total capacity increased and, generally speaking, delivery capacity improved. Some companies suffered from a lack of components, which caused some delays and rescheduling of assemblies

During the autumn of 2019, the uncertainty in the world economy has increased. Particularly, news from Germany concerning the reduction in industrial production has raised concern. Nevertheless, utilisation rates in the metal industry are good, but the number of orders have gradually decreased. The change is not yet significant, but it is still unclear what the situation is going to be in the winter.

Jame-Shaft’s year of 2019 started off really well. The demand increased strongly in January. At the same time, we started renovating the new premises in the factory, and when the new production area was finished, we started moving machines into to it create the new finishing department. This, however, created some challenges regarding delivery times, but thanks to some new employees and new investments, we could actually achieve and even exceeded the budgeted turnover for the first half of the year 2019. Because the business was slow in the autumn of 2018 compared with the previous years, the accounting year 2018/2019 resulted in the same turnover of 17 M€ as the year before. The current accounting period has started better than the previous year and the order base is approximately 10 % bigger than at the same time last year. However, the order base trend seems to be declining. The change is little, so let’s hope that it is only due to the normal seasonal variation. Often, the order base has been the lowest in October for several years in a row. From there on, the order book has gradually started growing again towards the spring. If this repeats we expect to achieve a bigger turnover at the end of the accounting period.

Big thanks to all of you who visited our stand at the Tampere Subcontracting Trade Fair!

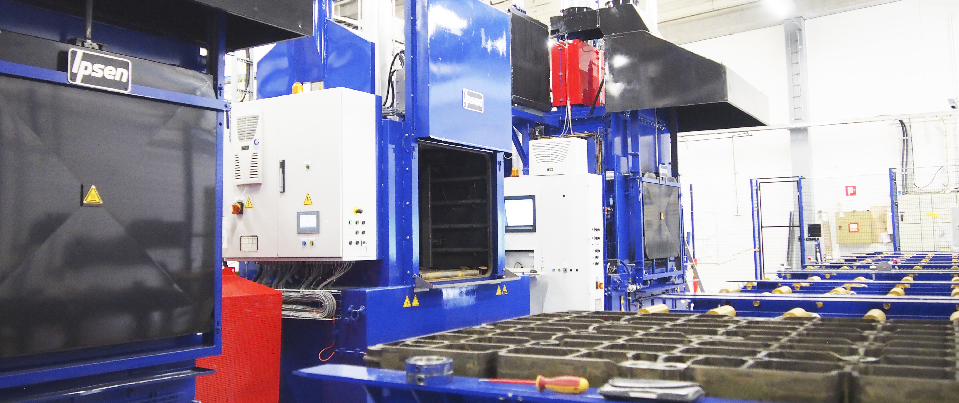

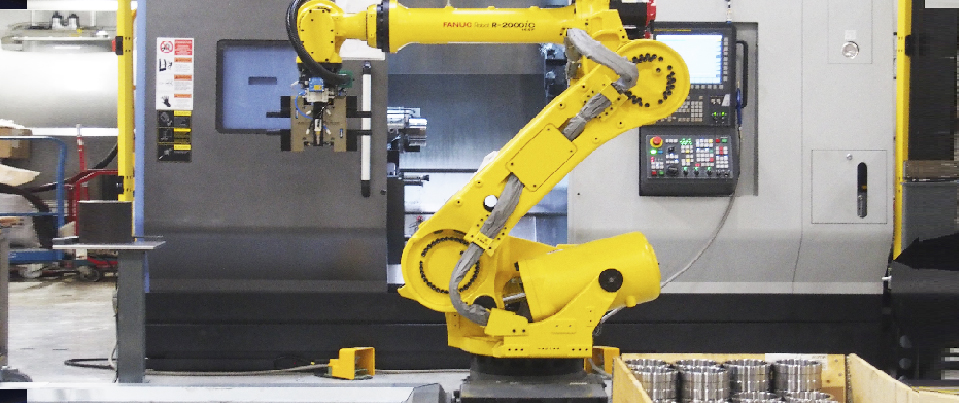

Despite the fact that the uncertainty in the economy has increased, it hasn’t changed our strategy or development plans. We plan accordingly to seek growth, and to ensure that, we need to be determined and continue building up capacity. We got more space, i.e. 1800 m2 in the same building at the beginning of the year. This new space has now been taken in use by the finishing department. In addition, a new cylindrical grinding machine has been located in there too. This is how we achieved more room for both machining and heat treatment. It is fair to say that all our departments have some available spaces where new machines can be placed if necessary.We are also working on a machining area dedicated for only nitrated components. This ensures better quality and makes production and capacity control easier. There will be all in all three turning machines in the machine complex all equipped with a robotic loading system. The first of which has already been installed and the first production series have been driven through. Another lathe is arriving in December and a third in January. We have also been planning a vertical machining center for the machine complex. The machining center will be ordered soon and delivered during the first quarter of 2020.

Also the new case hardening line has gradually been taken into use. The first production pieces came out in late September, and now the line is in production. We have had some minor issues with the new line, but all in all the new hardeningline is pretty much as we expected and will increase our case hardening capacity quite significantly. The end result looks really good, just what you could expect from a machine that is equipped with the latest technology. We have built the new hardening line keeping in mind that also another furnace could be installed if necessary.

Furthermore, we have continued developing different kinds of auxiliary systems. The key word has been ‘visuality’. Clear information about the factory, department and machine loading clarifies and optimises our daily operations and improves our service ability. In addition to this, we have carried on improving factory environment by cleaning working stations and by painting walls and floors. One important detail of how to utilise digitalisation is the use of electronic accident / near miss reporting by using WhatsApp. This helps us to make Jame-Shaft even more comfortable and safer place to work..

Let’s hope that the demand for our products continues to be good also in the near future.

Best wishes,

Mika Tuunainen

Managing Director

Jameshaft Oy